Technology

materials

We adopt the world's most advanced Heidelberg color management system for digital pre press management, ensuring high-quality printing

We have invested in various mechanical equipment to provide customers with diversified paper processing technologies

UV 、 Matte oil, partial printing oil, gloss matte glue, hot stamping, and other advanced and complete post-processing equipment, without the need for outsourcing, ensure the high quality of the products.

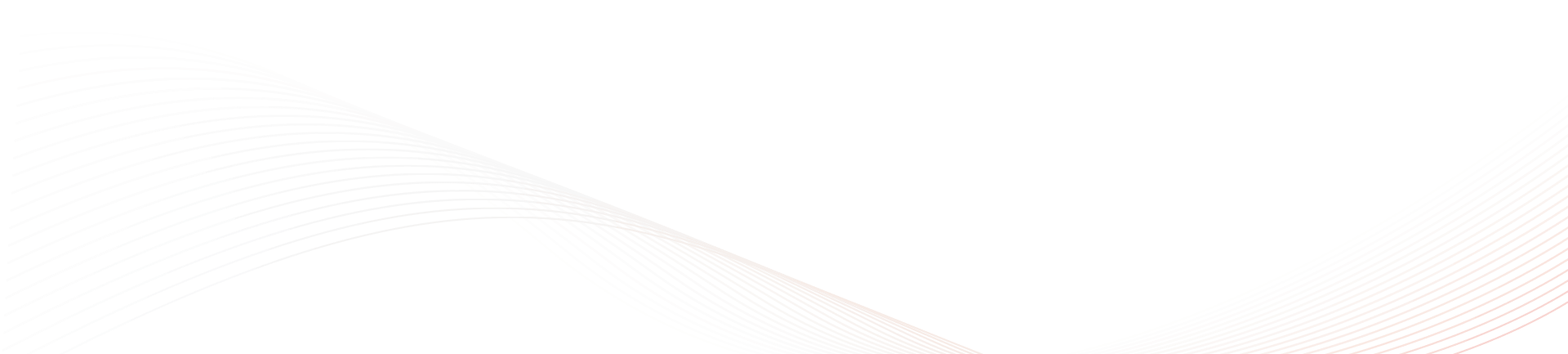

The design, content, personalized identification, color and material matching of brand packaging are increasingly attracting the attention of brand merchants and consumers

Design system guided by market demand, forming a design team of nearly 50 people

Deeply involved in the front-end development and design of customer products, creative design mainly includes graphic design, structural design, production process design, material design, and color management

A comprehensive post press process covering UV, laser, cat's eye, digital laser engraving, cold pressing, hot pressing, embossing, anti-counterfeiting refraction, etc. We recommend a reasonable process combination plan based on your product characteristics.

We value and adhere to process research and development, collaborate with upstream suppliers and downstream brand customers for collaborative innovation, and make more imaginations come true.

The frosted process replaces traditional glossy surfaces with hazy mist, softens the light, and highlights a luxurious style in a low-key manner. The frosted process can upgrade the texture of the picture, with details appearing and disappearing, creating a mysterious and profound visual level.

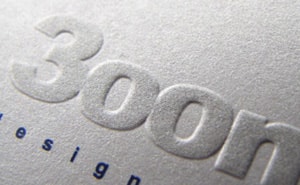

Cold pressing technology saves costs, provides excellent results, is highly adaptable, and can be flexibly combined with offset printing, flexographic printing, and other processes to easily meet diverse printing needs.

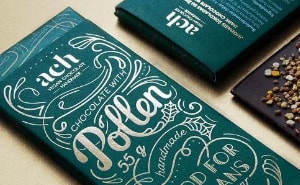

Extremely high precision, able to perfectly present subtle lines and complex patterns; Strong stability, consistent carving effect, endowing the product with unique texture and artistic value.

By squeezing with upper and lower roller molds, three-dimensional patterns are pressed onto the surface of the paper, creating a textured and visually layered texture without the need for ink.

By using high temperature and high pressure, the metal foil is transferred onto the surface of the paper, instantly coating the product with a luxurious outer layer. Its metallic luster is dazzling, and its lines are exquisite and accurate. Whether it is LOGO, pattern or text, it can shine.